Injection Technology

WEAsystec's injection technology comprises all contemporary methods for injection of elastomers into molds.

- Open-nozzle cold runner blocks

- Valve-gate cold runner blocks (hydraulic and pneumatic)

- ITM transfer chambers

- CITM transfer chambers (Cold Injection Transfer Molding)

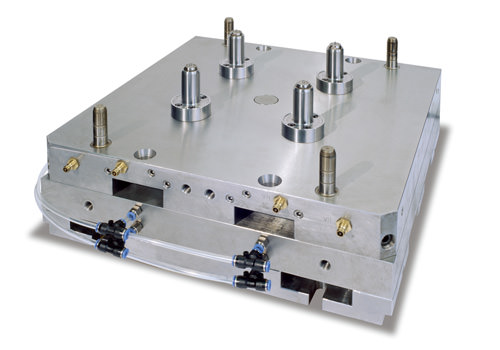

Cold Runners

Cold runners manufactured by WEAsystec feature a practice-oriented design and, due to their cost-efficient access, allow for economic planning ahead of part production. WEAsystec cold runners provide distinct advantages regarding:

- Quick material change

- Material savings

- Ergonomic handling

- Homogeneous tempering of the compound

- Reduction of heating and cycle times

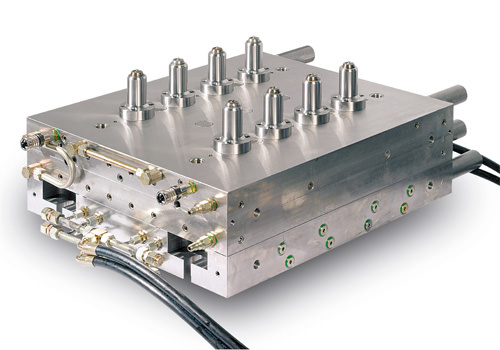

Valve-Gate Cold Runners

WEAsystec's needle-valve technology for cold runner blocks rates among the premium class in the field of cold runner technology. The benefits of WEAsystec valve-gate cold runners are:

- Standardized design

- Hydraulic or pneumatic needle actuation

- Symmetrical or non-symmetrical nozzle arrangement

- Separate control of needle valves for sequenced filling of molds ("sequence-fill")

- In-process volume flow control of individual nozzles for optimized flow-balance

- Processing of all common elastomers

CITM Transfer Chambers

CITM transfer chambers (Cold Injection Transfer Molding) represent enhanced versions of the conventional ITM technology. Removal of residual compound is no longer required thanks to the temperature-controlled transfer chamber. WEAsystec CITM chambers are characterized by:

- Round or rectangular chamber

- Small nozzle distance since individual cooling of nozzles is not required

- Suitable for all compounds up to 90° Shore A

- Individual cooling circuits for chamber and plunger

- Plunger finished with anti-friction coating

Contact

WEAsystec GmbH

Albert-Einstein-Str. 46

23617 Stockelsdorf - Germany

+49 (0) 451 / 87 206 - 20